When selecting tool cabinets for an auto repair shop, the core principles are: “safety and durability, efficient access, adaptability to different scenarios, and high cost-effectiveness.” In terms of products, the key considerations are: strong load-bearing capacity, detailed compartments, durability and rust prevention, and easy access.

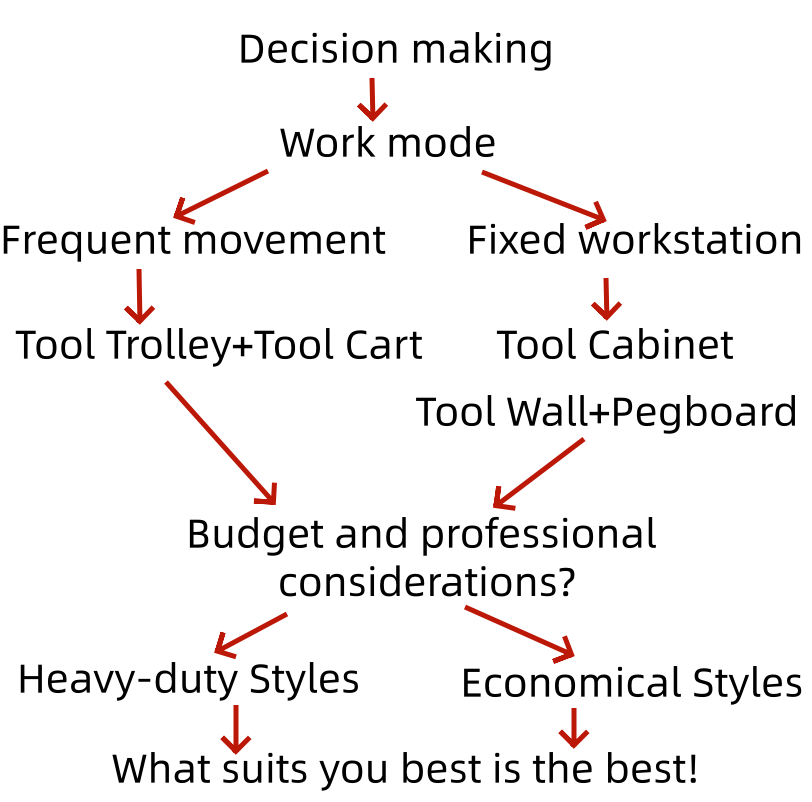

The choice of cabinet largely depends on the repair shop’s business scale, workflow, and budget. The following diagram outlines the core decision-making process:

1.Drawer tool cabinet (highly recommended, the first choice for general workstations):

1.1 Key Selling Points: Thickened cold-rolled steel plate (0.6mm-1.5mm optional), single drawer can support 35-100kg, securely holding wrenches, sockets, and automotive repair tool sets.

1.2 Suitable Scenarios: Suitable for machine repair and maintenance workstations. Used to categorize and store commonly used automotive repair tools. Drawers feature dividers and label slots, clearly separating screws, nuts, and small tools for easy searching.

1.3 Bonus Features: Includes anti-fall rails (preventing tools from falling out due to sudden pulling), a locking system (preventing tool loss), and casters (for easy movement next to vehicles).

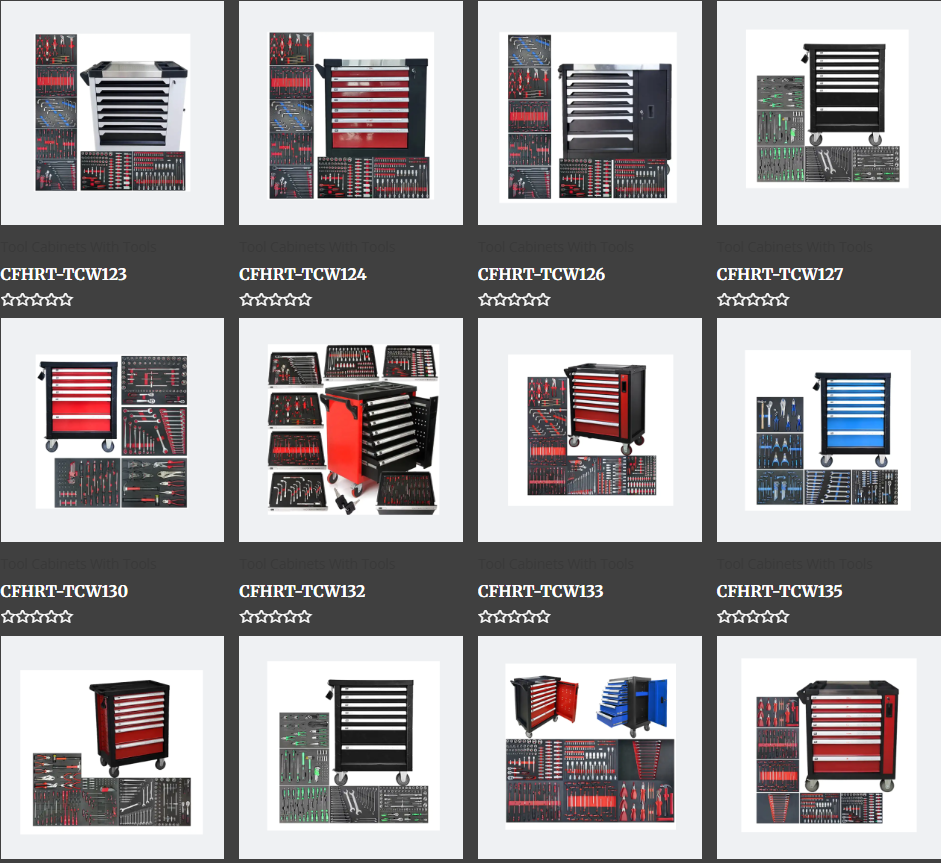

2.Mobile tool cart (preferred choice for maintenance work sites):

2.1 Key Selling Points: Lightweight cabinet with swivel wheels (with brakes), allowing for easy movement and making it ideal for mechanics working alongside their vehicles without needing to shuttle to the tool shed.

2.2 Suitable Scenarios: Suitable for workstations requiring on-site operations, such as engine repair and chassis maintenance. The upper shelf holds commonly used tools, while the lower shelf holds parts boxes or components awaiting repair.

2.3 Points to Note: Choose high-quality wheels with a load-bearing capacity of ≥200kg to prevent deformation under heavy loads; ideally, include side hooks for hanging pliers and screwdrivers.

3.Wall-mounted tool cabinet (saves space, essential for small workstations):

3.1 Key Selling Points: Saves floor space, ideal for repair shops with small workstations. Can be paired with pegboards and hooks to store long-handled or loose tools such as hammers, measuring tapes, and spray guns.

3.2 Suitable Scenarios: Suitable for sheet metal workstations, painting workstations, or for storing auxiliary tools. Recommended for use with heavy-duty tool cabinets for clearer division of labor.

3.3 Key Requirements: The wall-mounted bracket must be sturdy, with a board thickness ≥1.0mm to prevent heavy objects from falling off.

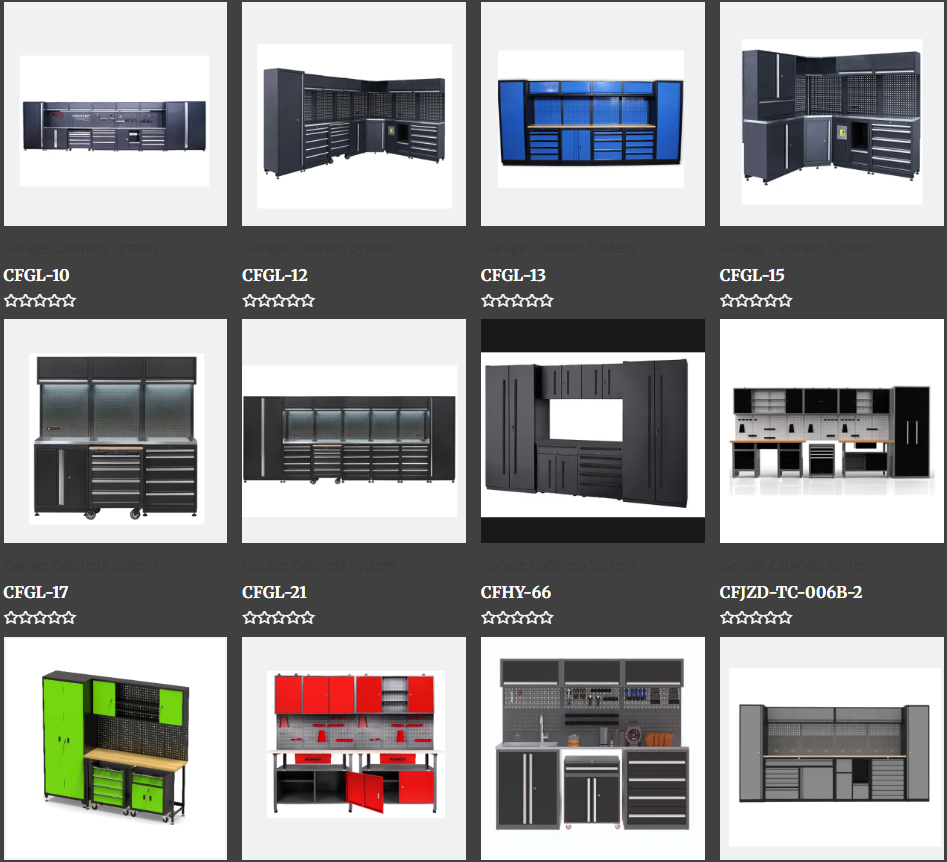

4.Modular workbench combination:

4.1 Key Selling Point: Convenient storage and retrieval of a large number of tools for easy access and maintenance

4.2 Suitable Scenarios: Entire workshop

5.Parts cabinet (a must-have for organizing small parts):

5.1 Key Selling Point: Multi-compartment drawer design, each compartment holds a small part, ideal for storing easily lost small items such as screws, washers, clips, and fuses.

5.2 Suitable Scenarios: Auxiliary storage for all workstations; recommended to be placed next to a heavy-duty tool cabinet for easy access to spare parts when retrieving tools.

Four key tips for choosing a tool cabinet for your auto repair shop:

Rust Prevention First:

Repair shops often experience oil and moisture buildup, so tool cabinets should have a powder-coated surface with a uniform, seamless coating to prevent rust and paint peeling.

Organize by Need:

Organize tools into cabinets for “frequently used tools + specialized tools + auxiliary materials.” For example, place machine repair tools in a heavy-duty cabinet, and paint tools in a separate, dry cabinet to avoid contamination.

Cost-Effectiveness:

Prioritize thicker materials (rails, wheels, locks). Don’t be tempted by cheap, thin models, as they will warp after a few months, ultimately costing more.

Consider Growth:

Tools will only increase, so it’s best to allow 20%-30% extra space when purchasing.

Based on the above factors, and considering the repair shop’s actual space, the number of tools, and usage frequency, choose a tool cabinet with moderate load-bearing capacity, a reasonable drawer structure, and durable materials. For professional auto repair shops (with ample budgets), brand-name products are recommended; for small repair shops or home use (with limited budgets), high-performance, cost-effective products are preferable.

The best one is the one that suits your needs!

Wishing you booming business!

Read More:

Case Study on Supply Chain Cost Reduction and Efficiency Improvement

Customer question: Why is there such a big price difference for the same tool cabinet?

Tool Cabinet/Chest/Box Buying Guide

Guía de compra de armarios/cofres/cajas para herramientas

Guia de compra de armário/baú/caixa de ferramentas

Tool Cabinet/Chest/Box Recommendations

Recomendaciones de armarios/cofres/cajas de herramientas

Recomendações para armário/baú/caixa de ferramentas

How to identify your target customer base (in the tool cabinet industry)?

Como identificar sua base de clientes-alvo (no setor de armários de ferramentas)?

¿Cómo identificar su base de clientes objetivo (en la industria de gabinetes de herramientas)?