Don’t let tools get in the way! Unlock the secrets of tool cabinet design

In daily life and work, whether it is a home DIY enthusiast, a professional craftsman, or a front-line worker in a factory workshop, all kinds of tools are indispensable. From simple screwdrivers and wrenches to complex power tools, these tools are like our right-hand men, helping us complete various tasks. However, when there are more and more tools, if there is no good way to store them, the tools will be disorganized and difficult to find, which will not only waste time but also affect work efficiency. At this time, the tool cabinet is like a magical “treasure box” and plays a vital role. It can not only classify and store various tools to make them orderly, but also protect the tools from damage and extend the service life of the tools. So, how is an excellent tool cabinet designed? Next, let us explore the mystery of tool cabinet design in depth.

- Careful consideration before design

(1) Clarify usage scenarios

Different usage scenarios have completely different requirements for tool cabinets. In the home environment, tool cabinets mainly serve DIY enthusiasts and daily home maintenance. They usually store some small hand tools, such as screwdrivers, wrenches, hammers, etc. The size is generally not too large, and more attention is paid to the balance between beauty and practicality. The color and style should be integrated with the home decoration style. At the same time, it should be easy to operate and move, and it is best to have rollers for easy use in different rooms. Some families will choose tool trolleys made of wood or plastic, which have a simple appearance and can be harmoniously matched with the home environment.

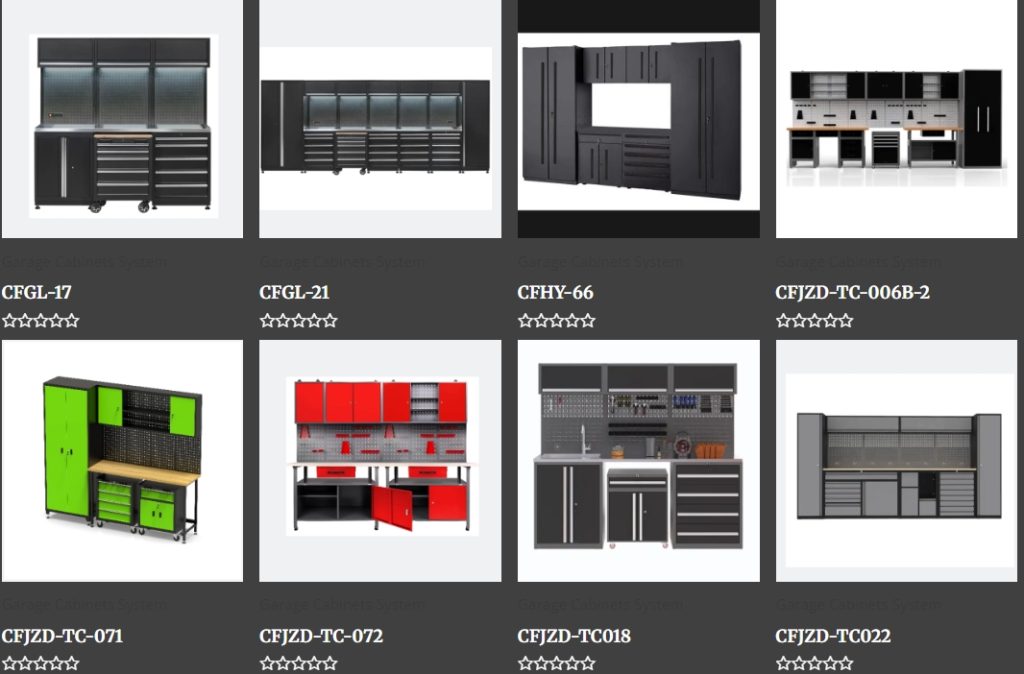

The tool cabinets in the factory workshop are another scene. There are many types and large numbers of tools in the factory, and there are many large and heavy tools, such as electric wrenches and large pliers. This requires the tool storage cabinet to have a strong load-bearing capacity and large storage space to meet the needs of classified storage of tools. Moreover, in order to adapt to the industrial production environment, the material of the tool storage cabinet must be strong and durable, able to withstand certain collisions and wear, and the surface treatment must also have good anti-rust and anti-corrosion properties. For example, many factories will choose heavy-duty tool cabinets with all-steel structures such as 56 inch/72 inch tool cabinet. The cabinets are thick and the drawers are made of high-quality rails to ensure stable operation under frequent use.

Looking at the field of power work, safety is the top priority. Power safety tool cabinets are mainly used to store safety protection tools and testing equipment such as insulating gloves, insulating boots, testers, grounding wires, etc. The performance of these tools is directly related to the life safety of power workers and the stable operation of the power system. Therefore, power safety tool cabinets need to have excellent insulation performance and good sealing performance to prevent dust and moisture from entering and affecting the insulation effect of the tools. It may also be necessary to equip temperature and humidity adjustment devices to ensure that the internal environment meets the storage requirements of the tools. Some intelligent power safety tool cabinets can monitor and adjust the temperature and humidity in the cabinet in real time, and also have functions such as tool in-place monitoring, which greatly improves the safety and convenience of tool management.

(2) Consider space layout

Space layout is an important factor that cannot be ignored in the design of tool cabinets. When choosing a tool cabinet, you must fully consider the size and shape of the placement space to ensure that the tool cabinet can be perfectly adapted without affecting the normal use of the surrounding environment.

If the space is spacious, such as a large factory workshop or a professional repair shop, you can choose a large, fully functional tool cabinet/tool chest. This type of tool cabinet usually has multiple drawers and multiple doors, which can provide sufficient storage space to meet the needs of classified storage of a large number of tools. You can also choose a modular tool cabinet workbench, which can be flexibly spliced according to the actual space and usage needs to create a personalized tool storage area.

On the contrary, if the space is limited, such as a small family garage or a storage room in an apartment, a small, compact tool trolley is more suitable. They occupy a small area and can make full use of limited space without making the space appear too crowded. For example, some wall-mounted tool cabinets can be directly installed on the wall, saving floor space, and are suitable for storing some commonly used small tools; there are also some foldable or retractable tool trolleys that can be stored when not in use, further reducing space occupancy.

In addition to the size of the space, the shape of the space will also affect the selection and placement of tool cabinets. In a rectangular space, tool storage cabinet can be placed along the longer wall to form a neat storage belt for easy access to tools; in a square or irregular space, it is necessary to make a clever layout according to the specific situation and choose tool cabinets of appropriate size and shape to make full use of every inch of space. For example, a triangular tool cabinet can be placed in the corner to maximize the use of space. At the same time, the direction of the tool cabinet’s door opening and drawer pull-out should also be considered to avoid conflicts with surrounding furniture, equipment or passages to ensure convenience and safety during use.

To be continued……

Read More:

Customer question: Why is there such a big price difference for the same tool cabinet?

Tool Cabinet/Chest/Box Buying Guide

Guía de compra de armarios/cofres/cajas para herramientas

Guia de compra de armário/baú/caixa de ferramentas

Tool Cabinet/Chest/Box Recommendations

Recomendaciones de armarios/cofres/cajas de herramientas

Recomendações para armário/baú/caixa de ferramentas

How to identify your target customer base (in the tool cabinet industry)?

Como identificar sua base de clientes-alvo (no setor de armários de ferramentas)?

¿Cómo identificar su base de clientes objetivo (en la industria de gabinetes de herramientas)?